Industry and academia partnerships, in various forms, can provide valuable educational experiences for students. With respect to additive manufacturing (AM) education, these partnerships become even more critical for several reasons:

Addressing Educator Knowledge Gaps

Many college professors lack formal education in additive manufacturing. Often, they need to take proactive steps to enhance their expertise, and this training is not always readily available, accessible, or affordable. Collaborating with industry professionals helps bridge AM knowledge gaps.

Keeping pace with Rapid Technological Advances

AM technologies, processes, and materials evolve at an exceptionally rapid pace. For those not working in the AM industry, it is difficult to keep pace. Industry partnerships allow academics to remain current with the latest AM trends and innovations.

Overcoming Financial Barriers

The costs of industrial additive manufacturing equipment and required infrastructure can be prohibitive for many universities. Establishing partnerships with the AM industry often can be the only viable way to access certain AM processes in a meaningful manner.

The Partnership Between EMU & Azoth, Inc.

In January 2023, Eastern Michigan University (EMU) began a pilot partnership with Azoth, Inc., based in Ann Arbor, Michigan. The partnership was formed to enhance the educational experience of EMU’s engineering technology students through project-based additive manufacturing education.

EMU is a midsize regional institution possessing multiple engineering and engineering technology programs. Over the years, EMU has proactively engaged in the field of additive manufacturing, with a focus on polymer processes.

Azoth is an additive manufacturing company disrupting small complex metal part production. Their team of engineers are experts in sinter-based additive manufacturing and focus on delivering high quality parts on-demand. Azoth not only possesses the required equipment but also possesses a strong desire to promote additive manufacturing education. They generously donated their personal time, equipment time, and materials to support this valuable educational endeavor.

The Pilot Project

During the Winter semester of 2023, the School of Engineering at EMU offered an introductory course on 3D Printing/Additive Manufacturing. The course featured guest lectures from industry experts from various companies such as, Voxeljet, Carbon, Trumpf, EOS, HP, Stratasys, and Azoth. In addition, Azoth initiated a metal binder jet project with the students with the following criteria:

· The class was divided into groups of four students each.

· Each group selected a part from one of the following industries: medical, tooling, consumer goods, or aerospace.

· Groups submitted a design concept report to Azoth specifying their part description, the industry the part serves, and why additive was chosen for this part (specifically, binder jetting)

· Groups also provided a CAD file for their part, a CAD file for the sinter support, a drawing with appropriate dimensions and tolerances, an Excel sheet with dimensions to be measured. The spreadsheet included nominal dimensions and a column for actual measurements.

· Azoth, Inc. was responsible for printing the parts, and once completed, students submitted a final report including actual produced part measurements.

Part Requirements

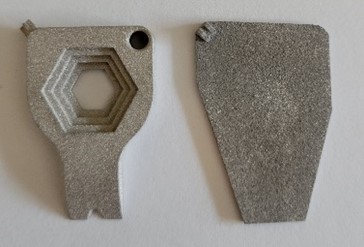

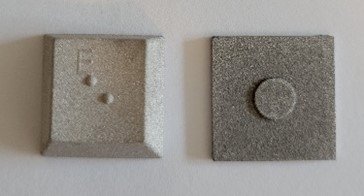

· Material: 17-4PH Stainless Steel

· Part size < 30mm in all overall dimensions (X, Y and Z)

· Name/logo embossed on the part as a unique identifier

· Sintering support (separate file – see design guide)

· The part must measure within 2% of all dimensions

· Part will have ~6-micron RA surface finish

Student Projects

Results/Lessons Learned

· Project Success Rate: Of the six projects, only one, the distal phalanx, faced printing challenges due to a design and time issue.

· Hands-on Experience for Students: This project gave students practical hands-on experience in designing parts specifically for metal binder jetting. With this exposure, it proved to be a significant learning opportunity.

· Time Management: Time was a factor that influenced the success of the pilot project. In hindsight, there wasn’t an opportunity for Azoth to follow up and support the students. In the future, projects such as this should be launched earlier in the semester.

· Industry Insights: Students gained valuable insight into how companies operate and what their priorities are. This first-hand experience provided students a better appreciation of the dynamics of the business world.

· Mutual Learning: Joint partnerships like these provide a better understanding between companies and college students. Endeavors such as EMU & Azoth can further develop companies’ appreciation of the diverse backgrounds of students and additional insights into the operational constraints faced by universities.

Conclusion

Overall the pilot partnership and project were a success with many positive takeaways and lessons learned. Both EMU and Azoth look forward to future industry/academia partnerships.

Sign up today for a free Essential Membership to Automation Alley to keep your finger on the pulse of digital transformation in Michigan and beyond.

This article featured contributions from the staff of EMU and Azoth. EMU contributors include Phil Rufe, Assistant Professor, Product Design Engineering Technology, and Andy Le, Additive Manufacturing Lab Manager. Azoth contributors include Cody Cochran, General Manager and Co-Founder, and John Travis, Metal AM Applications Engineer.