A digital subscription to Automation Alley gets you access to exclusive gated content, including the 2022 Technology in Industry Report.

Technology is changing the way we make things. From a facilitator of marginal efficiencies to a powerful enabler of disruptive innovation, Industry 4.0, with software at its core, is creating more flexible systems that allow manufacturers to pivot in a fast-changing world—unlocking data, creating new business models, and connecting us in new and exciting ways.

Our globally recognized Technology in Industry Report is back for 2022, focused on the pillars of Industry 4.0 that we see driving global manufacturing into the future: Software-first Transformation, Additive Manufacturing, and Distributed Manufacturing.

With insights from our growing manufacturing and technology ecosystem, the 2022 Report is a comprehensive, collaborative effort—filled with emerging trends, challenges and opportunities, expert interviews, and cases studies from industry leaders—that will arm you with all the knowledge you need to help guide your business into the future.

About Chapter 3: Distributed Manufacturing

What is Distributed Manufacturing & How Could it Change the World?

Distributed manufacturing is experiencing a renaissance fueled by Industry 4.0 technologies combined with changes in consumer behavior, geopolitical and environmental concerns. The recent pandemic and its aftermath of supply chain issues have only helped accelerate the quest for distributed manufacturing. In this white paper, Chinedum Okwudire, Associate Professor, Mechanical Engineering, University of Michigan, says a variety of business models are possible within distributed manufacturing. However, to reap the full benefits of distributed manufacturing, he argues technologies, policies, and other infrastructure must be trained toward incorporating democratization into distributed manufacturing. From a technological standpoint, the building blocks for democratized models of distributed manufacturing already exist in Industry 4.0, but these technologies must continue to be harnessed to create frameworks that enable the expansion of distributed manufacturing.

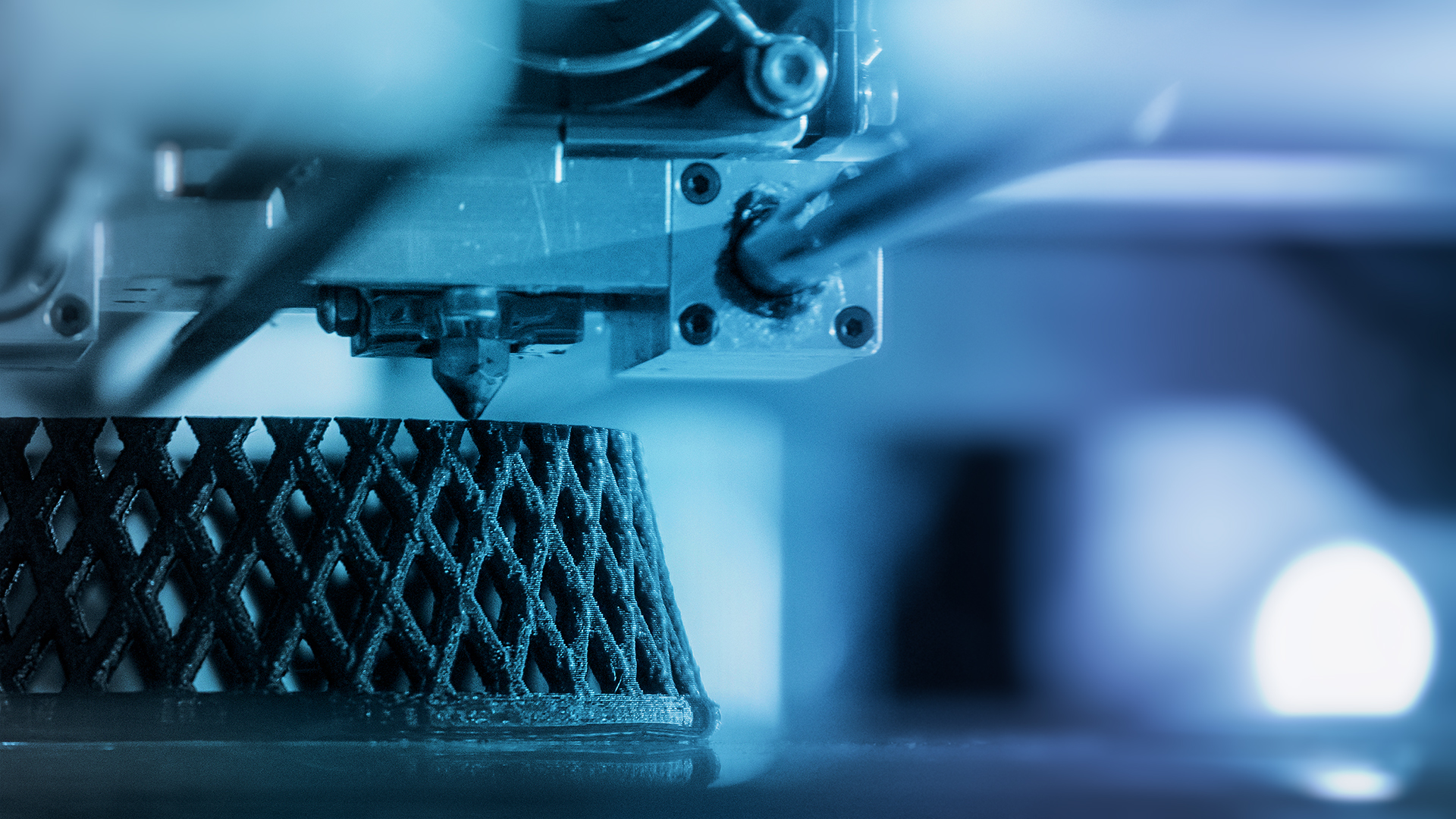

Case Study: Project DIAMOnD’s Successful Activation of Distributed 3D Printing Network to Assist Ukraine During Wartime Serves as Proof of Concept for a Future of Additive, Digitally Connected Supply Chains

.jpg)

Russia’s recent invasion of Ukraine disrupted manufacturing supply chains for many critical medical supplies. When the Ukrainian government put out an urgent request for life-saving tourniquet parts, Automation Alley, working with Markforged, activated Project DIAMOnD, the world’s largest distributed manufacturing network, to 3D print the critical supplies on demand. The experience yielded several key learnings. This case study highlights the key takeaways, which represent necessary considerations for successful deployment of any large, distributed manufacturing network, as well as the industry’s path to bringing additive’s supply chain benefits to mainstream use at scale. Read the case study here.

The Importance of Blockchain in Distributed Manufacturing

Ongoing supply chain disruption and product availability delays have emphasize the critical role that distributed manufacturing can play in today’s rapidly evolving industries. In this article, you’ll learn how technologies like 3D printing and cloud computing have propelled the idea of distributed manufacturing to the forefront, and how some of this model’s significant challenges can be addressed using blockchain technology.

Automation Alley is a World Economic Forum Advanced Manufacturing Hub (AMHUB) for North America and a nonprofit Industry 4.0 knowledge center with a global outlook and a regional focus. We facilitate public-private partnerships by connecting industry, education and government to fuel Michigan's economy.